| Environmental temperature | Working temperature:- 5℃-55℃ Storage temperature:- 40℃-70℃ |

Each master can be equipped with a potentiometer | 2 | |

| Handle | Equipped with zero position mechanical self-locking | Rated operating frequency | 1200 times/h (600 times/h) | |

| Handle operation force | Not exceeding 25N (50N) | Mechanical life | 1.5 million times per direction of motion | |

| Movement direction | Has gear sense and automatic zeroing | |||

| Maximum operating direction | 4 | Contact characteristics | Rated power frequency | AC 50Hz (60Hz) |

| Maximum gear positions in each direction | 5 (6) | Rated working voltage | 380V(440V) | |

| Number of controllable institutions | 4 | Rated working current | 3A 10A 32A 63A 100A | |

| Maximum number of contacts per institution | 12(21) | Electrical lifespan | 1 million times | |

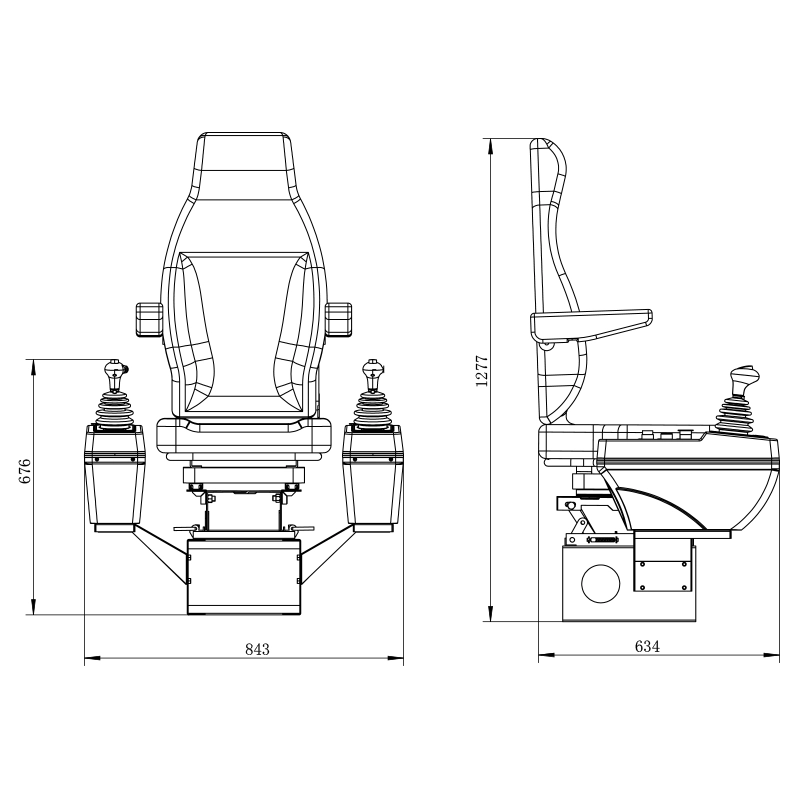

QT22 Crane Console

Standards

- GB/T 14048.1 General Rules for Low-voltage Switchgear and Controlgear

- GB/T 14048.5 Low-voltage Switchgear and Controlgear – Part 5 – 1

- JB/T 6748 Consoles for Cranes

Scope of Application

The QT22 crane console is mainly used in control circuits with an alternating current of 50 Hz (60 Hz) and a rated voltage of 380 V (440 V) or below. It is designed to control the starting, speed regulation, braking, reversing, and other special functions of motors in hoisting and conveying machinery, enabling the linked operation of dual mechanisms. All types of integral consoles can be made into rotary ones. Different seats can be selected according to different usage environments. This series of consoles has been widely applied to various types of mechanical equipment in industries such as ports, water transportation, railways, metallurgy, mines, power, and construction.

Structural Features

This series of crane consoles is available in both integral and split – type designs. The outer shell components of the products can be formed either by stamping metal materials or injection – molding engineering plastics, presenting an aesthetically pleasing appearance.

The crane consoles are equipped with various models of master controllers developed by our company. They offer a comfortable operating experience, with a distinct tactile feel and clearly defined gear positions.

The operating mechanism is provided with an automatic reset function and a zero – position self – locking device. The contacts use Schneider contacts and self – made contacts, ensuring safe and reliable operation and a long service life.

The wiring, installation, and maintenance of electrical components are convenient. The crane consoles are equipped with various indicator lights and control buttons, and it is easy to install additional devices such as touch screens and mimic panels.

The seats have adjustment functions for height, forward – backward position, backrest angle, and weight adaptation, which can meet the comfortable operation needs of people with different body types.

Get a quote

If you have any comments or suggestions, please contact us and we will provide you with the best quality service

Please leave your contact information, we will contact you as soon as possible