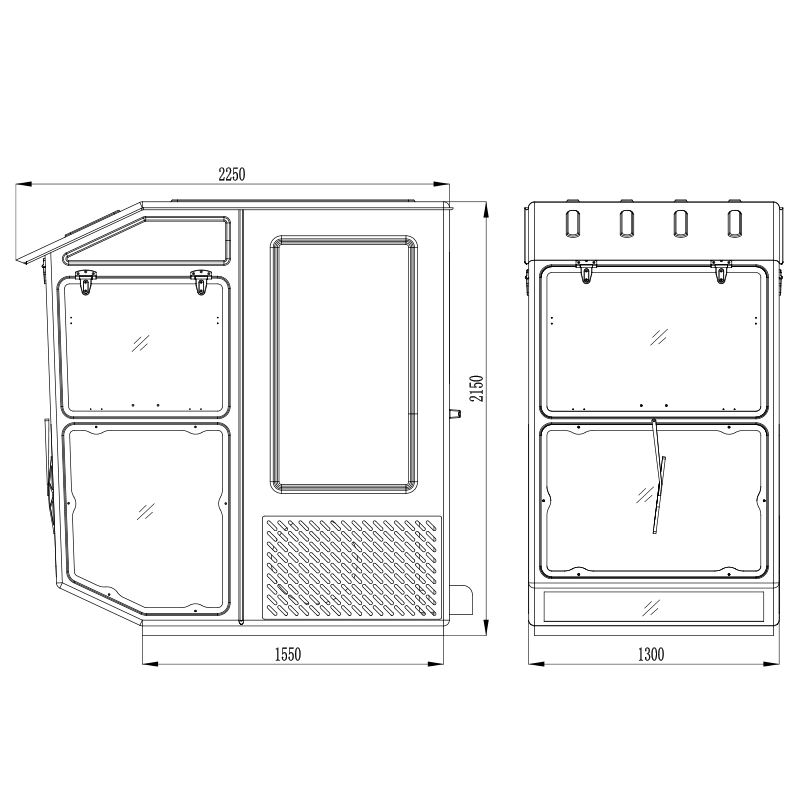

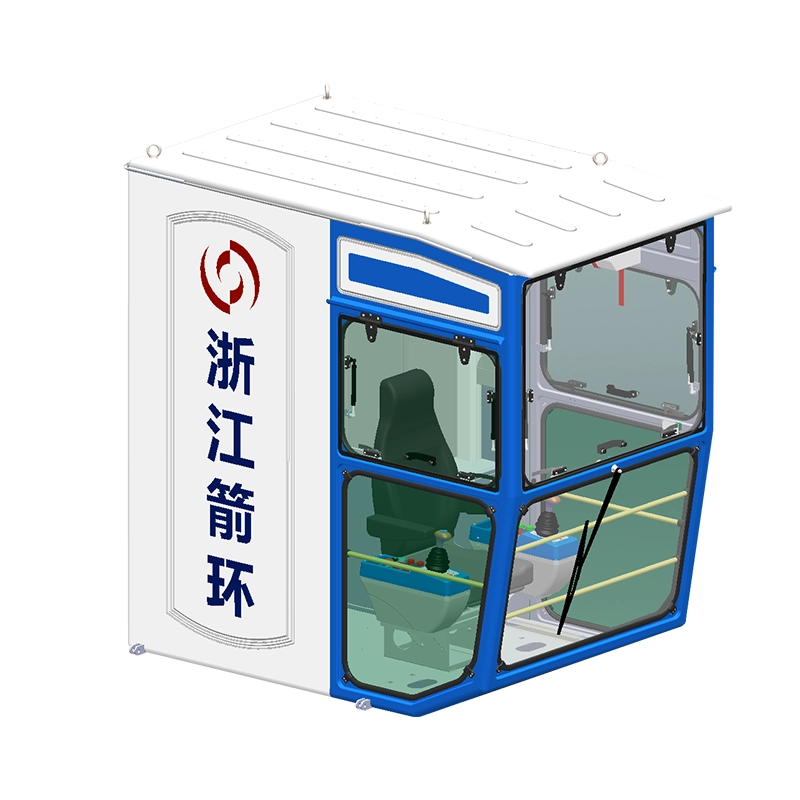

SQT12 tower crane cab

Manufacturing Processes

- Cold-rolled stretch stamping

- Cutting with a 3D laser cutter

- Suspended spot welding on the assembly line

- Whole-machine electrophoresis on the assembly line

- Painting on the assembly line

- Assembly on the assembly line

Standard Configuration

- Lighting fixture

- Switch and socket

- Manual windshield wiper

- Tempered glass

- Curtain

- Front top sliding windows on both the left and right sides

- Fixed front bottom and rear windows on both the left and right sides

Optional Configuration

- Linkage console

- Driver equipment box

- Air conditioner

- Fire extinguisher

- Fan

- Cup holder

- Coat and hat rack

- Folder

Product Features

- Long service life (≥ 10 years): The entire sheet metal part of the product is treated with electrophoresis, offering exceptional corrosion resistance. There are no weak spots in corrosion protection for the inner and outer panels of the body as well as the inner cavities of the profiles, significantly enhancing the structural durability. The electrophoretic paint film has a thickness of up to 20μm and can withstand a salt spray test for over 500 hours.

- High – quality product: Both the sheet metal and interior components are formed through single – step stamping, resulting in a seamless interior and exterior with excellent flatness and meticulous attention to detail. The product goes through a powder coating process on the assembly line, followed by drying and curing, which gives it a smooth surface and strong adhesion. The whole machine is formed by spot – welding, ensuring good integrity and sufficient strength to meet hoisting requirements.

- Short production cycle and prompt delivery: With product standardization, assembly – line manufacturing, and a high degree of automation, the manufacturing efficiency is greatly improved. This shortens the production cycle and guarantees timely delivery.

- Comfortable indoor operation: The product adopts automotive interior design concepts, creating a beautiful and comfortable indoor working environment.

- Personalized customization of standardized products: We offer a variety of models and sizes for customers to choose from. Accessories such as body color, logo, windshield wiper, curtain, fan, and socket can be selected by customers, enabling personalized configuration of standardized products.

More Products

Get a quote

If you have any comments or suggestions, please contact us and we will provide you with the best quality service

Please leave your contact information, we will contact you as soon as possible

.webp)