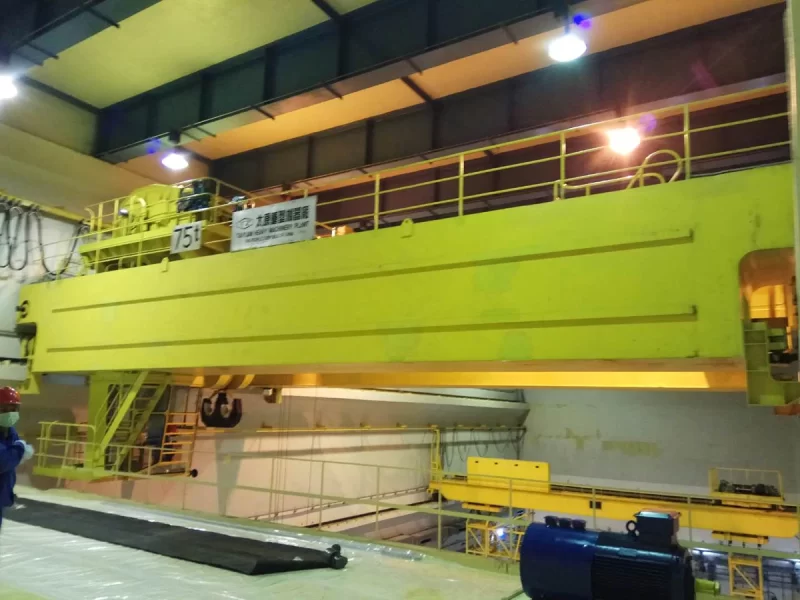

The main mechanisms of this overhead crane include the main and auxiliary hoisting mechanisms, the main and auxiliary trolley mechanisms, and the gantry traveling mechanism. Among them, there are four main hoisting motors, with two in standby and two in use, each driven by one of the four frequency converters. The single auxiliary hoisting motor is independently driven by one frequency converter. One frequency converter is shared by the main and auxiliary trolleys for switching control. There are four gantry motors, with two of them driven by each of the two frequency converters. This configuration meets the requirement that even if one frequency converter fails, the other two motors can still drive the gantry to move slowly.

The frequency converters used in this machine are from ABB’s ACS800 series. The hoisting mechanism adopts closed – loop DTC control, while the translational mechanism uses open – loop SCALAR control. The PLC is from Siemens’ S7 – 300 series, and an ET200M remote station is set on the control console. The whole – machine control adopts Profibus – DP communication control.

Feihua Wireless Intelligent Crane Control System

This control system employs two sets of Siemens PLCs, and Mitsubishi frequency converters are used for each mechanism. Absolute encoders are installed on each mechanism, and a Siemens touch screen is set on the operating console. Wireless data transmission is…